On this difficult journey in the production area where a small movement may disrupt the whole process and precision is the foundation of all, the millipede of (IPM) inches per minute calculator comes to the assistance of the user through the jungle of efficiency. Through this immersive investigation, we dive deep into the essence of this indispensable machine, broadly revealing its many uses, diverse applications, and how it is only a step towards the future.

Table of Contents

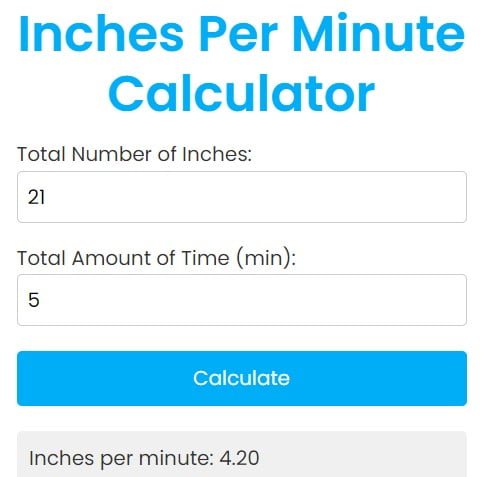

How to Use the Inches Per Minute Calculator

Harnessing the power of the Inches Per Minute Calculator is a straightforward yet profound process:

- Input Parameters: Begin by entering the total number of inches and the total amount of time.

- Calculate Feed Rate: Once the parameters are entered, the calculator computes the optimal feed rate in inches per minute based on the input data.

- Adjust as Needed: Machinists can then fine-tune the calculated feed rate based on specific requirements, such as surface finish, tool wear, or machining strategy.

Deciphering the Essence of the Inches Per Minute Calculator

What stands at the center of the Inches Per Minute Calculator is the assumption of accuracy and quality of the engineering workmanship. This component controls the speed, the direction, and the tool movements in a very accurate way but it does not normally detect the accuracy of the movements of the parts. Having sophisticated algorithms and variable parameters, it endows frontline machinists and shop floor operators with the ability to generate and conduct the harmony of operational efficiencies.

Example: Putting Theory into Practice

Let’s, now, take into account a situation where there is a machinist assigned to mill aluminum components of different forms with the aid of carbide end mills. The operation is to make use of the spindle speed, number of cutting edges, and material type in order to find the best feed rate value for this particular operation. Empowered with those facts, they go ahead to use the complicated machinery in a systematic manner resulting in better outcomes than they had anticipated and in less time than normal.

Formula: Unraveling the Mathematics

Behind the intuitive interface of the Inches Per Minute Calculator lies a complex web of mathematical algorithms. While the specifics may vary depending on the calculator tool used, the fundamental formula for calculating feed rate typically involves the following parameters:

Anatomy of Efficiency: A Deeper Dive

To truly grasp the prowess of the Inches Per Minute Calculator, let us dissect its elemental components:

1. Spindle Speed (RPM): The spindle speed truly shows the pulse of the machining process’s speed, however, it regulates the speed of productivity in manufacturing as well. Machinists can play with RPM settings to set the rhythm of a cut and making tradeoffs between speed and gentleness is necessary, so optimum quality is developed.

2. Feed Rate Mastery: The correctness of the animal feeding rate can be regarded as the essence of good machining. The Inches Per Minute Calculator serves as the craftsmen’s dancing partner guiding them in that complex and very interesting tango between the tool and the material to adjust feed rates until that perfect harmony in terms of efficiency and precision is achieved.

3. Material Dynamics: Whether it is the basic wood, or the structural metal, even if it is a tune of properties of machining process, a unique approach is required. Just like from the rhythmical flow of aluminum azure buzzing to the noise of the massive solid steel triumphant roar, the task is exponentially abstract in its shape once you have come to the Inches per Minute Calculator that is supposed to weave aces the magic of interchangeability of hundreds of sound prolongation materials.

Applications Across the Pantheon of Industries

The versatility of the Inches Per Minute Calculator transcends the boundaries of industry, leaving an indelible mark across diverse domains:

1. Precision Manufacturing: For the precision manufacturing realm, where the tolerance is in microns scale, the Inches Per Minute (IPM) Calculator is the one who is the maestro who is in charge of directing the music of accuracy. The materialization of artistic ideas with the help of cutting speeds of synchronization, elevates a craft to the quality unattainable by others.

2. CNC Machining Marvels: In the part-automation CNC machining field, where precision goes hand-in-hand with automation, the Inches Per Minute Calculator plays the tune by acting as a maestro that writhes each minute errantly with deadly precision. For instance, when CNC machines literally and perfectly carve the most complicated patterns, it may just be the sound of the IPM Calculator playing the role of the humble conductor.

3. Artisanal Craftsmanship: The apprentice Inches Per Minute Calculator watches in the closets of artisan studios, traditionalists who are curious about newer technologies. It seizes the opportunity and absorbs all of the knowledge from the senior craftsman, and later uses it in the science of creation today. In the hands of the sculptor, a chisel magically becomes the brush of a painter; the smoothness of a plane envisions the formation of wind-blown hair and dust-covered strands through the skill of a woodworker.

Maximizing Efficiency: Strategies for Mastery

In the pursuit of machining mastery, where every cut is a brushstroke upon the canvas of creation, the Inches Per Minute Calculator unveils a treasure trove of strategies for maximizing efficiency:

1. Parameter Prowess: The first step towards mastering something is when we acknowledge the limits and learn to work within the scope of our capabilities. Machinists immersed in the realm of RPM, feed rates, and material properties, lift up their craft from a state of imperfection to its finer side.

2. Tooling Triumphs: Likewise, the selection of a tool or an instrument is like a composer’s decision to select a way to play the symphony. Machinists are loyal shepherds who handpick their aggregate of a cutting-edge armory those giving happen to be in synch with the precise feed rates guaranteeing all meticulousness of symphony of n-transpose efficiency and effectiveness.

3. Iterative Innovation: The goal of advancement is neither the arrival nor the endpoint but the journey of consistent shaping. Machinists enter a world of creativity, and improvising while doing their work, which makes them rise to the rank of a true artist, somebody whose initial craftwork is a grand design.

Conclusion: The Overture to Excellence

In the world of manufacturing where a myriad of figures are mathematically computed, the Inches Per Minute Calculator announces the opening of the curtain for the operations that follow, championing better output and precision. We are journeying through the maze of productivity, may we follow its signpost among the strands of innovation, the stitches one by one, as we make tracks on the sign of its meaning.

From one to the other, in manufacturing, we build our memoria, our magnum opus, a Latin expression that means the greatest masterpiece, a testament to the ability of engineering accuracy to transform. It is not only about adding a few strides at the end; more importantly, it is about infusing life into metallic bodies and marking our names in the history of industry. In the end, it is about leaving a badge of mastery that should rebound from age to age.

FAQs

How do I calculate inches per minute?

To calculate inches per minute (IPM), you typically need to know the spindle speed (in revolutions per minute or RPM) and the feed rate (in inches per revolution or IPR). The formula for calculating IPM is:

IPM=RPM×IPR

Where:

- IPMIPM = Inches per minute

- RPMRPM = Revolutions per minute

- IPRIPR = Inches per revolution (feed rate)

What is the formula for inches per minute welding?

The formula for calculating inches per minute in welding typically involves determining the travel speed of the welding torch or electrode. The formula is similar to the general IPM formula mentioned above.

How to convert RPM to IPM?

To convert RPM (Revolutions per Minute) to IPM (Inches per Minute), you need to know the feed rate (in inches per revolution) of the cutting tool. Then, you can use the formula mentioned in question 1.

How do you convert inches into minutes?

Inches and minutes are two different units of measurement and cannot be directly converted into one another. Inches measure length or distance, while minutes measure time. The conversion between these units would depend on the specific context or calculation being performed.

What is the formula for IPM?

The formula for calculating IPM is

How do you calculate inches formula?

The formula for calculating inches depends on what you are measuring. For example, to find the area of a rectangle in square inches, you would use the formula: Area=Length×Width. To convert from other units to inches, you would use conversion factors specific to the units involved.