Introduction:

Modern production and infrastructure support their backbone; there cannot be paper without wood or electric power without coal; however, there is no steel without steel. Despite the complexity of the steel pricing, knowing the cost per pound of steel, excluding the secondary factors, is important for the platform users intending to leverage their budget and purchasing strategies properly. This hefty piece will shed light on the inconsistency of the price of the steel which is made by rolling it on the pound and the complexity of that.

Table of Contents

How to Use:

To calculate the cost per pound of steel, follow these steps:

- Identify the type and grade of steel required for your project or application.

- Determine the form and dimensions of the steel product needed (e.g., sheets, bars, tubes).

- Consult with steel suppliers or utilize online resources to obtain current pricing information.

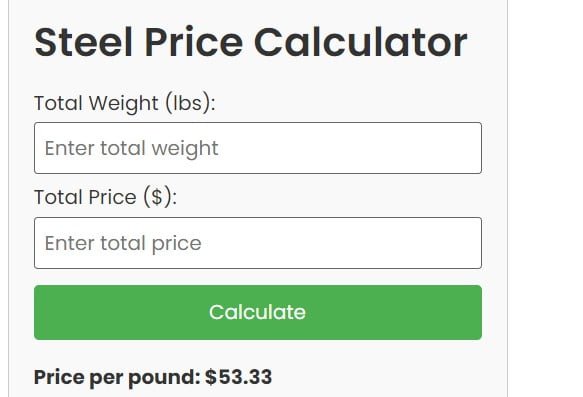

- Input relevant parameters into a pricing calculator or formula.

- Calculate the cost per pound of steel using the provided formula or online tool.

Example:

Let’s consider an example to illustrate the calculation of the price of steel per pound:

Steel Grade: ASTM A36 (Standard mild steel) Form: Steel Plates Dimensions: 1/4 inch thick, 4 feet wide, 8 feet long Market Conditions: Stable, with moderate demand and sufficient supply

Using an online steel price calculator, we input the above parameters and obtain the following result:

Price per Steel Plate: $500 Weight of Steel Plate: 4 feet (width) x 8 feet (length) x 1/4 inch (thickness) x 0.2836 pounds/inch³ (density of steel) = 226.88 pounds Cost per Pound of Steel: $500 ÷ 226.88 pounds = $2.20 per pound

Formula:

The formula to calculate the price per pound of steel is as follows:

Price per Pound of Steel = Total Cost of Steel Product ÷ Total Weight of Steel Product

Factors Influencing the Price of Steel Per Pound:

- Raw Material Costs: The cost of the raw materials, mainly iron ore and scrap metal are the key reasons behind the increase in the price of steel, per pound. The mystery arising from a mixture variance of raw material prices is influenced by supply-demand imbalance, mining regulations, and geopolitical instinct which may determine the cost-effectiveness of making steel per pound.

- Energy Prices and Production Costs: Energy-intensive operations in manufacturing (for instance, blast furnace and EAF steel production) make steel critically strike-sensitive to energy prices. Fluctuations in energy prices, in conjunction with environmental rules and technology advancement, may impact the costs of production which in turn leads to the price within 1 lb of steel.

- Labor and Overhead Expenses: The image of the working class needed to be depicted through augmentation of their wages, operational costs, and overhead expenses, which in turn constitute the final price at which the steel sells. Absorption of costs of labor productive, labor regulation, maintenance of the facility, and, overhead address all manufacturing art of a labor-intensive nature.

- Environmental Regulations and Sustainability Initiatives: With the rising green production practices and the continuous efforts to revamp all steel processes with environmentally friendly technologies, the steel industry is now more environmentally conscious than before. Investments in such emission reduction measures as for instance waste management and energy-efficient processes may involve some extra costs that may be carried out to consumers, and this can lead to a rise in the price of steel if one pound is taken as a unit.

- Tariffs, Trade Policies, and Global Supply Chains: Steep steel import tariffs, conditions for exports and movements of goods, as well as geopolitical tensions can destabilize all supply chain areas all over the world affecting price volatility as well as the amount of uncertainty. In addition to this, trade disagreements, protective policies, and dumping duties set by governments can make the steel market unstable, being a reason for price fluctuation and per pound price for both inland and overseas clients.

- Technological Innovations and Product Differentiation: Technology expansion, the arrival of not-along way products, and the advent of new types of steel make steel quality and performance better. New steels, that have a specific purpose, like serious steels or corrosion-resistant alloys, are more expensive, and money is charged per pound for their improved properties and characteristics.

- Regulatory Compliance and Quality Standards: In compliance with higher quality standards, formality certifications, and regulatory requirements, the production and shipment of steel are burdened with a higher level of complexity. In the course of quality control, testing, certification, and traceability, other costs, such as quality, arise and product price for the manufacturers and consumers is determined in this way.

Calculating the Price of Steel Per Pound:

To reveal an accurate price for a pound of steel, utilizing online sources, industry databases, and expertise from professional steel suppliers will prove a helpful step. Price indices, market forecasts, and historical data can be used to discover pricing trends and project them in the future, and they can then be used to create policies to buy cheaper goods and services.

Conclusion:

In summary, the cost per pound of steel calls for a broader view encompassing the multi-faceted factors determining the dynamics of the steel sector. Pondering some elements including input materials costs, fuel costs, employees’ expenses, environmental laws-Environmental regulations, trade policies, technological innovations, and quality will give a stakeholder a clear idea of what could happen concerning steel prices. It does not matter whether it is building a construction project, developing a factory, or working to improve infrastructure decisions about the optimal choices in such and with regards to steel procurement is of utmost importance in improving performance, minimizing resource wastage, and supporting sustainability.

This article demonstrates how dynamic the steel pricing dynamics are and explains how strategic planning, market intelligence, and adaptability make up a set of tools that one can always rely on for success in a dynamic and ever-evolving business environment.

FAQs

How much is 1 pound of steel cost?

The cost of 1 pound of steel can vary depending on factors such as the type, grade, and quality of the steel, as well as current market conditions. To determine the exact cost, it’s advisable to consult with steel suppliers or utilize online resources for pricing information.

How much is 1kg of steel?

Similarly, the cost of 1 kilogram (kg) of steel is subject to fluctuation based on various factors such as steel grade, form, dimensions, and market conditions. Pricing can be obtained from steel suppliers or through online resources specializing in steel pricing.

What is the cost of 1 ton of steel?

The cost of 1 metric ton (1,000 kilograms) of steel depends on the factors mentioned earlier, including steel grade, form, quality, and prevailing market conditions. To obtain the current cost of 1 ton of steel, it’s recommended to consult with steel suppliers or refer to pricing indices and market reports.

How much does steel cost per kg?

The cost of steel per kilogram can fluctuate based on the factors influencing steel pricing, as outlined above. To determine the current cost of steel per kilogram, individuals can reach out to steel suppliers or utilize online resources for pricing information.

Is steel sold by the pound?

Yes, steel is commonly sold by weight, and pricing is often quoted per pound. However, in some regions or industries, steel may also be sold by the kilogram or metric ton. The choice of unit for pricing steel depends on regional preferences, market conventions, and the specific requirements of buyers and sellers.

How is steel priced?

Steel is typically priced based on several factors including raw material costs, production expenses, market demand, and industry trends. The price of steel can vary depending on the type, grade, form, dimensions, and quality of the steel product. Factors such as energy prices, labor costs, transportation expenses, and regulatory compliance also influence steel pricing. Additionally, global economic conditions, trade policies, and currency fluctuations play a significant role in determining steel prices. Steel pricing is commonly expressed per pound, per kilogram, or per metric ton, depending on regional preferences and market conventions.