Introduction:

Regarding plastic manufacturing, such as extrusion or molding, precision is the primary element. Plastic products employ packaging materials and industrial components, among others, this property and dimension are of great importance. The one major part that comes to mind is figuring out the blow-up ratio, the high-importance component of the entire plastic extrusion. In this comprehensive guide, we’ll delve into the concept of blow up ratio, its calculation methods, and the essential formulas every manufacturer should know.

Table of Contents

What is Blow Up Ratio?

The Bow down ratio (BUR) is an important metric for the extrusion of plastic, particularly when it comes to processes of film extrusion and tubing manufacturing. It is a depiction of the product’s width after extrusion in relation to the width of the die itself. To put it simply, the ratings reflect the measurement of the amount of plastic blow-up or stretch as during the extrusion process.

Blow-Up Ratio Calculation:

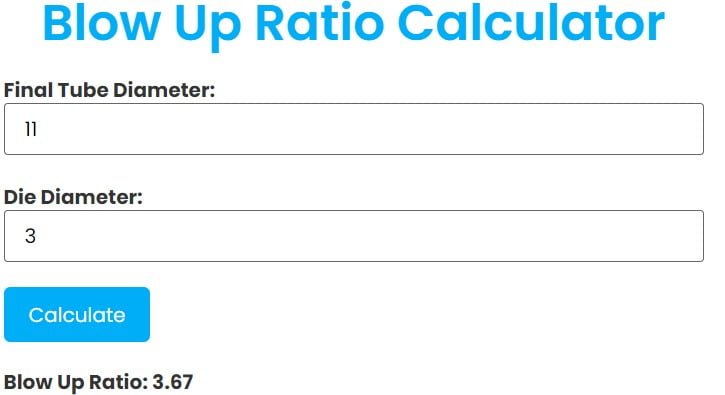

Calculating the blow up ratio involves determining the relationship between the dimensions of the extrusion die and the final product. There are various methods for calculating BUR, depending on the shape of the extruded product.

For cylindrical products like tubes or pipes, the blow-up ratio can be calculated using the formula: Blow Up Ratio = Final Diameter / Die Diameter

If you’re dealing with flat products such as film or sheeting, the formula changes slightly: Blow Up Ratio = Final Width / Die Width

In some cases, where the circumference or perimeter is more relevant than the diameter or width, you can use these formulas accordingly.

Blow Up Ratio Formula:

The blow up ratio formula serves as the foundation for ensuring precise manufacturing processes. By understanding this formula, manufacturers can adjust their equipment settings and die designs to achieve the desired product dimensions.

FORMULA:

Understanding the significance of this formula empowers manufacturers to optimize their extrusion processes for efficiency and quality.

Example:

Let’s consider an example of producing a plastic film with a target width of 500 mm using an extrusion die with a width of 100 mm. Using the blow-up ratio formula for flat products: Blow Up Ratio = Final Width / Die Width Blow-Up Ratio = 500 mm / 100 mm Blow-Up Ratio = 5

In this example, the blow-up ratio is 5, indicating that the plastic film must be expanded five times its original width to achieve the desired dimensions.

Practical Application:

Carrying out blow-up ratio describing in manufacturing real-live practical cases is an issue of detail and accuracy Producers have to take into account all those properties of the material, processing conditions, and the exact specifications yielding the decided product.

Engineers and operators could make their extrusion design & optimization process more efficient via live accuracy blow up ratio calculator and software tools. This kind of software gives an organized way of varying die size, speed of screws, and other factors until the right ratio of blow-up is achieved.

Furthermore, it is essential to have an idea about this ratio in the relationship of the material’s properties so as to have reproducible output. Respectively, these types of polymers are elastic or have high melt strengths, which can affect the blow-up ratio and the end product quality.

Benefits of Optimizing Blow-Up Ratio:

Optimizing the blow-up ratio offers several benefits for plastic manufacturers:

- Dimensional Accuracy: The performance of NTPM is to be able to control the rate of expansion and to produce consistent dimensions of the products that correspond to the customer’s specifications.

- Material Savings: The refinement of the extrusion operation involving the adjustment of the blow-up ratio to the minimum will result in the material waste decrease, therefore we can talk about lowering the expenses and growth of the efficacy.

- Enhanced Product Performance: Duly inflated products are likely to showcase these specific mechanical properties which include strongness to pull apart and not so easy to get through, thus the durability and performance of a product are affected.

- Process Efficiency: Regulating the air supply ratio supports smooth production, minimizing the interruption and increasing production, especially, the throughput rate.

Conclusion:

In the sphere of blow molding, which is extremely important for good product quality and process efficiency, the flow of the blow ratio is one of the lines that people should master. Unlike the conventional extrusion process, additive manufacturing gives the manufacturers a detailed understanding of the formulas and calculations. Therefore, it is easier for the manufacturers to constantly refine their processes and services in the new technology.

By the use of blown up ratio calculating, the knowledge and experience gained chemicals can be navigated with all the uncertainty. At the forefront of modern manufacturing, curved lamination is a vital optimizing technology that enables the long-term success of plastic manufacturers.

FAQs

How do you calculate blow-up ratio?

The blow-up ratio (BUR) is calculated by dividing the final dimensions of the extruded product by the dimensions of the original extrusion die. For cylindrical products like tubes or pipes, use the formula: Final Diameter / Die Diameter. For flat products such as film or sheeting, use: Final Width / Die Width.

What do you mean by blow-up ratio?

Blow-up ratio refers to the ratio of the final dimensions of an extruded plastic product to the dimensions of the original extrusion die. It determines how much the plastic material is expanded or inflated during the extrusion process, impacting product properties such as thickness and strength.

What is blow-up ratio in blow molding?

In blow molding, the blow-up ratio (BUR) is the ratio of the volume of the final molded part to the volume of the parison (hollow tube) extruded from the die. It determines the extent to which the parison is inflated to conform to the shape of the mold cavity during the blowing process.

What is the blow-up ratio for LDPE?

The blow-up ratio for LDPE (Low-Density Polyethylene) can vary depending on factors such as the desired product specifications and processing conditions. Generally, blow-up ratios for LDPE films range from 2 to 4.

What is the blow-up ratio for HDPE?

Similarly to LDPE, the blow-up ratio for HDPE (High-Density Polyethylene) can vary based on specific requirements and processing parameters. Typically, blow-up ratios for HDPE films range from 2.5 to 5.

What are the basics of blown film?

Blown film extrusion is a manufacturing process used to produce thin plastic films for various applications such as packaging, agriculture, and construction. The process involves melting plastic resin pellets in an extruder and then passing the molten polymer through a circular die. Air is introduced through a mandrel within the die, inflating the polymer into a bubble or tube. The bubble is stretched and cooled to form a thin film, which is then flattened and wound onto rolls for further processing or packaging.